Screw-type composting plant RA-X

In this project, household food waste in Sri Lanka is recycled as compost instead of chemical fertilizers using the screw-type composting plant RA-X, which is then used by farmers to grow crops.

Each household collects garbage separately, and only household food waste is collected and used as raw material. Agricultural waste is used as a moisture conditioner to produce high-quality compost, which is then sold to neighboring farmers.

Currently, 20 units of RA-X are in operation in Sri Lanka, backing up agriculture throughout the country.

イ RA-X composting system to solve the problem of separating food scraps!

|

When collecting garbage, food waste in plastic bags, plastics, bottles, cans, etc. can be thrown into the RA-X. |

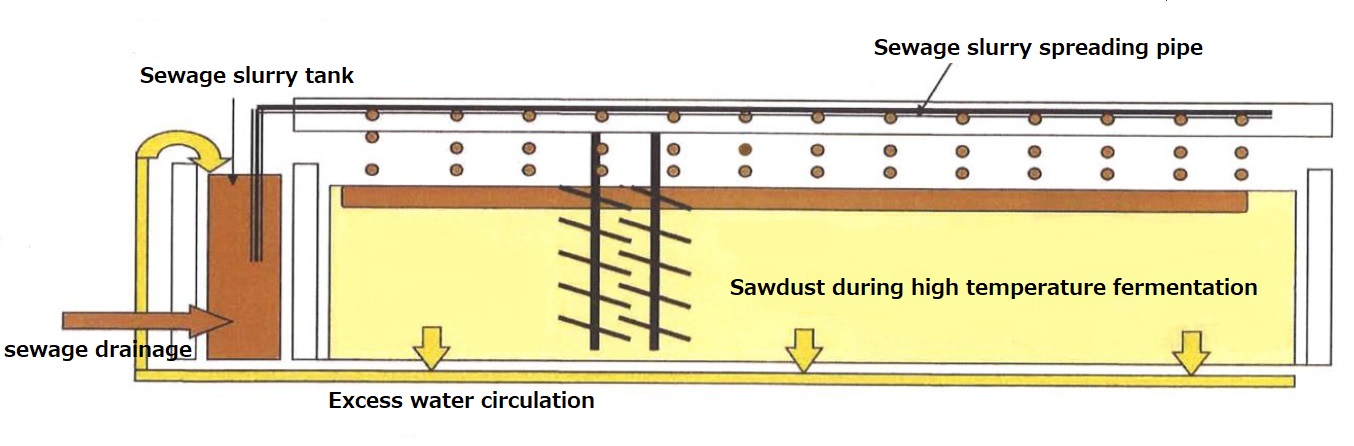

イ Features of Ra-x = Complete aerobic fermentation process

(1) Easy maintenance and low running cost(2)Low temperature drop during agitation and energy-saving fermentation

(3) Simultaneous treatment of solids and sewage is possible.

(4) High-temperature fermentation is possible even in cold regions.

(5)Low odor generation

イ Ra-x in Sri Lanka

イ Low odor and short processing time

Why no bad odor is generated during compostingThe most important aerobic bacteria of composting are allowed to grow in every corner, creating an environment that does not allow anaerobic bacteria to operate.

Screw agitation is a major know-how, which results in the deposition of raw materials without compaction, and air is spread to every corner of the compost.

Screw agitation ensures air permeability even when moisture content is slightly high, maintaining aerobic bacteria.

Reasons why the time period can be shortened

The elements necessary for composting are (1) nutrient source, (2) moisture, (3) air (oxygen), (4) microorganisms, (5) temperature, and (6) maturation period.

Conventional turnover methods have the disadvantage of temporarily lowering the fermentation temperature due to exposure to outside air.

With screw agitation, the sediment is agitated up and down in the sediment, so only the top of the sediment is exposed to the outside air and the high temperature can be maintained. This made it possible to shorten the time period by 50% compared to other turnaround processes.

Customers who viewed this item also viewed these products

|

|

|

|

|

|

Japanese products expected to increase sales in the future

|

|

|

|

|

|