Okadora Cyclone dryer for food waste, fishery waste and sludge

The Okadora Cyclone Dryer is a patented, wastewater-free, odor-free, and completely pollution-free drying system developed by an oil refinery plant design engineer that destroys the conventional way of thinking about technology.

The Okadora Cyclone Dryer is a patented, wastewater-free, odor-free, and completely pollution-free drying system developed by an oil refinery plant design engineer that destroys the conventional way of thinking about technology.Thirty years have passed since the equipment was completed, and it is the most reliable dryer in Japan, with over 400 units in use in all at major manufacturing plants, famous hotels, and large shopping centers in Japan.

It is a revolutionary drying system that can dry both solids and liquids such as food waste, marine products, and sludge discharged from factories.

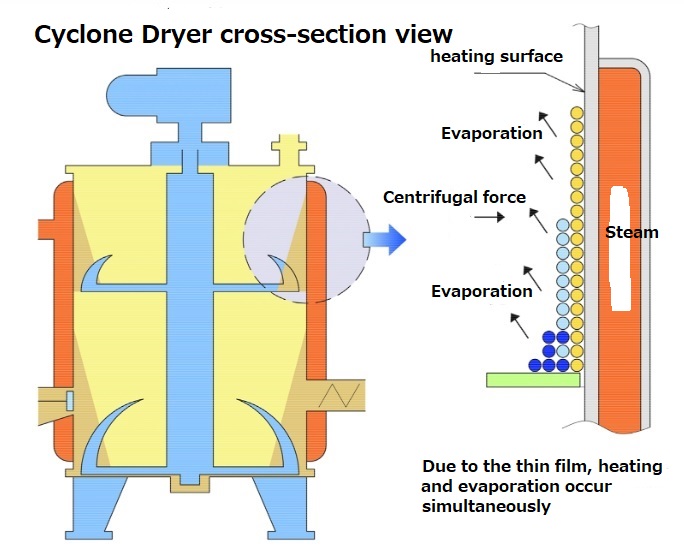

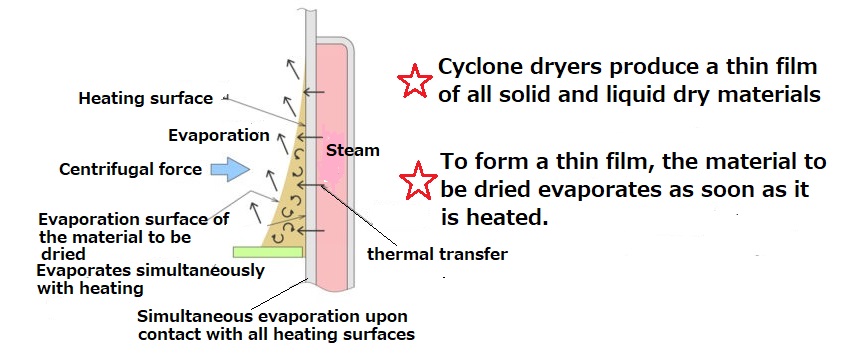

As the fins rotate, the material to be dried is simultaneously scraped up onto the vertical heating surface and pushed into a thin film on the wall surface.

In this process, heavier materials, i.e., those with higher moisture content, are preferentially pushed to the heating surface by the action of centrifugal force.

Then, the heated material with lower moisture content moves to the evaporation surface, further promoting moisture evaporation.

This process is repeated as needed.

The heating surface and the evaporation surface become infinitely equal as the dried material becomes a thin film and contacts the heating surface, and the contact speed with the heating surface is fast, causing turbulent contact at the thin film boundary.

The cyclone fins, as the name implies, can also scrape up slurries and other fluid materials and bring them into thin-film contact with the heated surface.

イ Major features of the cyclone dryer

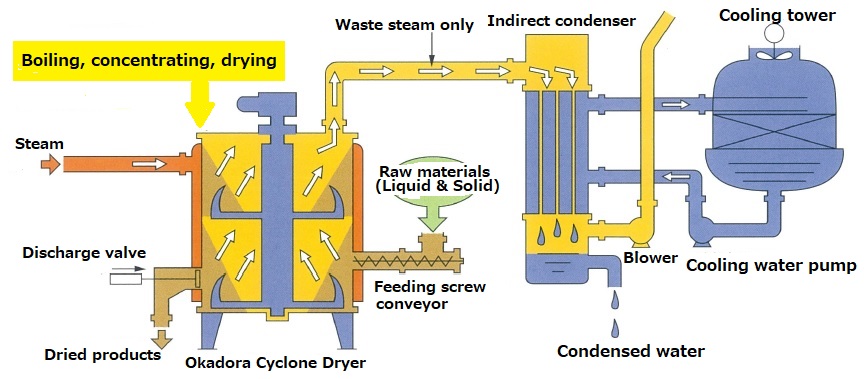

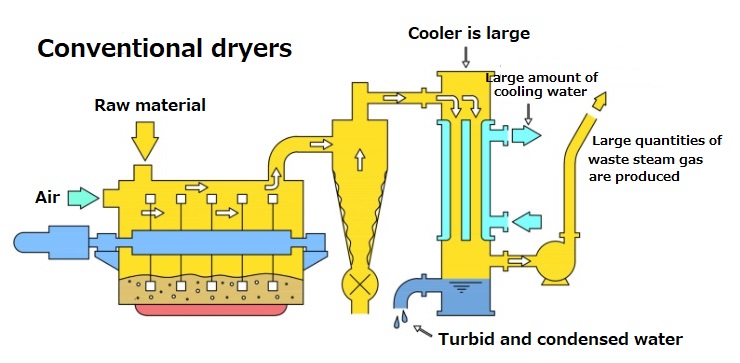

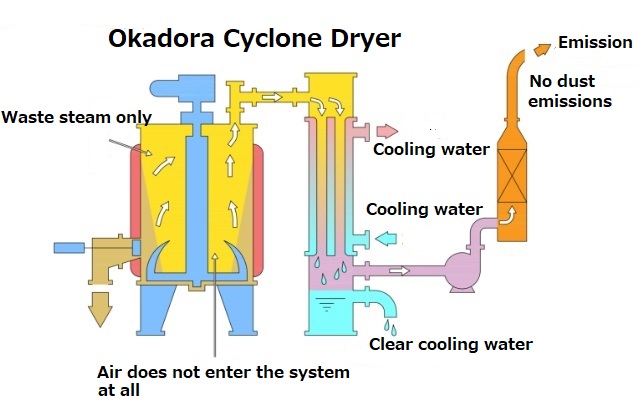

No waste gas is generatedConventional dryers introduce carrier air to transfer evaporated moisture from dried materials, so even if waste vapor is cooled, the carrier air becomes waste gas and a large amount of waste gas with odor is released into the atmosphere. Since the Okadora dryer does not require carrier air, most of the waste vapor from the dried material becomes condensate when cooled, and no waste gas is emitted.

No dust emissions

No dust emissionsConventional dryers introduce a large volume of carrier air to move the evaporated vapor of the dried product, which generates a large amount of dust gas involving dust from the dried product, thus requiring a large dust collection facility. In addition, dust is also mixed in the condensed water, resulting in the discharge of polluted condensate. The Okadora dryer requires no carrier air at all and generates almost no dust. Therefore, no dust collector is needed, and the condensate is discharged as clear water.

Very low energy loss

Conventional dryers introduce a large amount of carrier air to transfer the evaporated moisture of dried materials to the outside. At this time, a large amount of retained heat inside the dryer is also released to the outside at the same time, which lowers the temperature inside the dryer and significantly reduces the drying efficiency of the dryer.

Since the Okadora dryer does not require carrier air, there is little energy loss in terms of heat dissipation due to carrier air heat transfer, and the dryer efficiency is not reduced.

Less than a quarter of the size of a conventional dryer

The Okadora dryer can provide heat to dry materials at a rate more than four times faster than a conventional dryer, thus providing the same drying capacity in less than one-fourth the size of a conventional dryer.

Capable of drying evenly to ultra-low moisture content (10 to 0.1%)

Since the dried material is in contact with the heating surface in a thin film and a constant centrifugal force is applied, the material with more moisture is naturally pushed to the heating surface by centrifugal force, preferentially heated to evaporate the moisture, and when it becomes lighter, it is transferred and exchanged with the material with more moisture. This process is repeated as needed, enabling even drying to ultra-low moisture content.

The ideal evaporation efficiency is the one in which the heating area and the evaporation area are as close to equal as possible. This allows heating and evaporation to occur at the same time.

Thermal efficiency more than 4 times higher than conventional dryers

In the Okadora dryer, the material to be dried comes into contact with the heated surface at an extremely high speed of 10 to 30 m/sec or more, resulting in a high temperature rise rate. However, if the heat transfer is fast but the evaporation rate is slow, the dryer will only hold heat in the dried material and will not be able to dry it.

As shown in the figure below, the Okadora dryer brings the dry material into contact with the heating surface in a thin film, so the evaporation area of the dry material is equal to or slightly larger than the heating area. Since evaporation occurs simultaneously with heating, the given heat quantity is evaporated and dissipated at the same time, achieving a balance between heat transfer rate and heat evaporation and dissipation rate, resulting in extremely high drying efficiency.

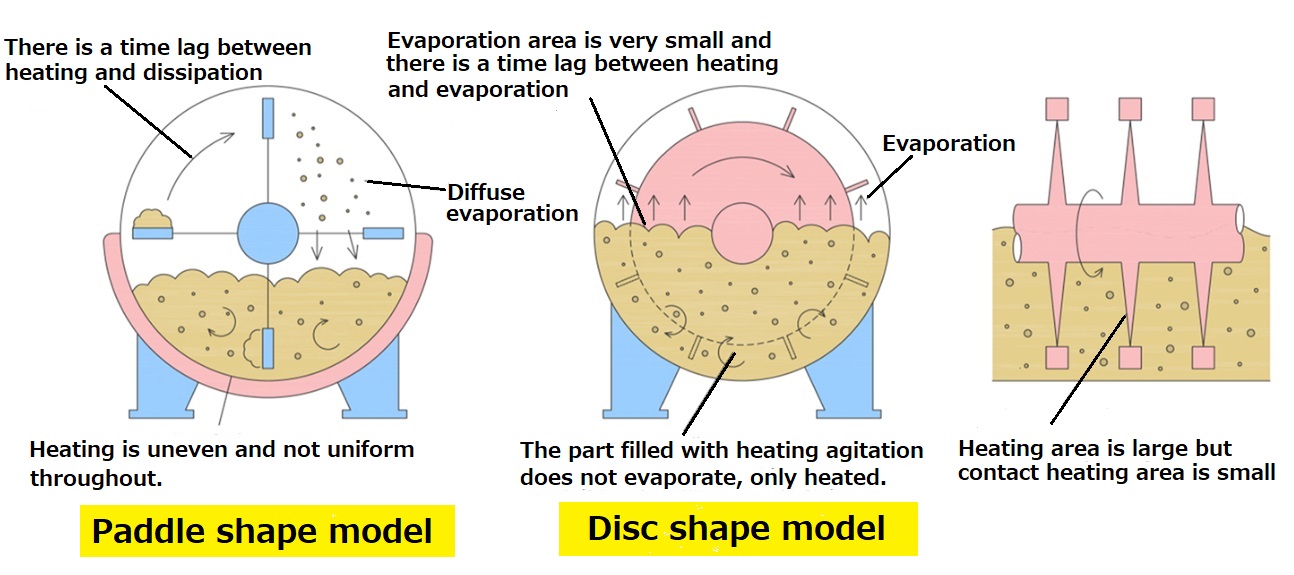

Conventional dryers have a time lag between heating and evaporation, and the heat retained in the dried material is not evaporated and dissipated simultaneously on average, resulting in very poor drying efficiency.

Conventional horizontal dryers are half full of the material to be dried, while horizontal paddle dryers and horizontal disk dryers only heat and agitate the material to be dried, with no water evaporation at all in the filled portion of the dryer.

Conventional horizontal dryers are half full of the material to be dried, while horizontal paddle dryers and horizontal disk dryers only heat and agitate the material to be dried, with no water evaporation at all in the filled portion of the dryer.In a horizontal paddle dryer, evaporation and dissipation occurs only in the dried material scraped up by the scraping blade, and evaporation occurs only in the very small surface area that is being heated and agitated.

In a horizontal disk dryer, the heating area is large, so there is heating power, but the amount of evaporation per surface area of the material to be dried is very small, and the amount of agitation and dissipation is also small, as in a paddle dryer. However, in the case of paddle dryers, the heating area is small, so no matter how good the dissipation by agitation is, the drying efficiency will be poor.

The biggest disadvantage of horizontal dryers is that the drying efficiency is very poor because of the time difference between heating and evaporation.

Foreign Material Separation - No Sorting Needed

Foreign Material Separation - No Sorting NeededThe internal structure is very simple, and at the same time, the space between the blades and the heating surface is specially designed to prevent foreign matter from getting caught, so the Okadora dryer will not easily stop even if foreign matter, plastic packaging, trays, etc. are mixed in with the food scraps.

(However, be careful not to throw in a large amount of foreign matter.)

Easy expansion

Because of the vertical type and centrifugal heating surface contact heating characteristics, raw materials can be easily transferred between dryers during expansion, allowing for expansion one by one in accordance with the factory production volume. There is no need to anticipate the plant's production volume several years after the initial installation.

Products with the required moisture content can be produced

The continuous batch system allows a small amount of product to be fed at one time, and the drying time can be set from 20 to 60 minutes, so the drying time can be shortened or lengthened, and the required moisture content of the product can be automatically extracted.

Dried products are of high quality

Conventional dryers require a residence time three times longer than the unit processing time for drying, which inevitably results in a loss of quality. The Okadora Cyclone Dryer uses a vertical centrifugal thin-film contact system, which enables rapid contact speed on the heated surface and even drying in a short time, resulting in high quality dried products with no deterioration or unevenness.

High yield of dried products such as food and feed

Since almost no waste gas is produced and no dust accompanying waste gas is generated, the yield rate of dried products is extremely high.

Inexpensive equipment cost

The vertical design of the dryer, which is less than a quarter the size of a conventional dryer, significantly reduces not only the main unit, but also the associated boiler equipment, electrical equipment, foundation work, building work, and site area used, resulting in lower overall facility costs.

Can be installed anywhere

Because of its simple structure and low overall weight, it can be easily installed on building rooftops and indoors. The vertical design also makes it possible to install between devices, between buildings and fences, and in other locations that were almost unthinkable under conventional wisdom.

Extremely easy to maintain

The main unit has a simple structure with only upper and lower bearings (commercially available) and a gird motor (world-class manufacturer) as rotating parts.

Easy operation and unmanned operation

The basic drying process of the Okadora dryer consists only of feeding raw materials, indirect steam heating, and discharging dried products, and can be easily operated even by amateurs. In addition, because it is a simple operation process, unmanned automatic operation is possible.

One Okadora dryer handles all dried materials, both liquid and solid

The Okadora dryer uses a vertical thin-film centrifugal heating system that can handle all types of dried materials, from liquid to solid, by changing the rotation speed and centrifugal force. Operation can be easily changed from liquid to solid with only the touch of a button.

イ Type of waste

|

|

|

|

|

|

イ More than 400 cyclone dryers installed in Japan alone

Japanese products expected to increase sales in the future

|

|

|

|

|

|