Super Waste Processor magnetic organic waste decoposer

イ Super Waste Processor is full-blown magnetic decomposer for big volume waste

|

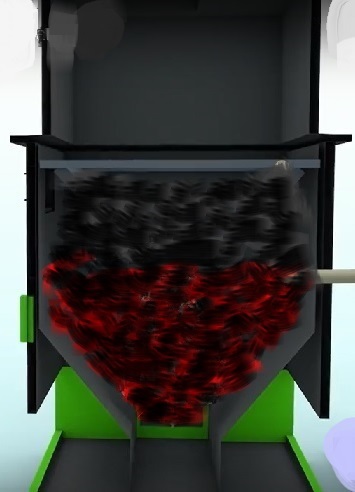

Super Waste Processor is a revolutionary magnetic thermal organic waste decomposition treatment device that incinerates plastics, petrochemical products, styrofoam, rubber, solidified paint, wood, packaging materials, cardboard, clothing, etc, through incomplete combustion, reducing them to ash approximately 1/300. |

イ Main features of Super Waste Processor

1. SWP can be installed anywhere as long as there is a roof and electricity.2. SWP operates solely on electricity without using any fuel.

3. SWP has low power consumption, resulting in low running costs.

4. SWP does not emit carbon monoxide, carbon dioxide, odors, and consistently achieves values well below the standard limits in exhaust gas measurement tests.

5. Ash volume is reduced to approximately 1/300 of the initial waste.

6. Since ash is small amount, the disposal is sufficient once a month.

7. SWP enables efficient waste processing by continuous waste input.

8. The compact and simple device structure minimizes breakdowns and simplifies maintenance.

9. Tar is completely burned and solidifies into a small amount, which disappears when reintroduced into the SWP.

イ Process of Super Waste Processor

イ Processable materials

| Treatable materials Plastics, styrofoam, rubber, hardened paint, cardboard, paper, lumber, pallets, cloth, work gloves, clothing, tires, paper, organic materials with low moisture content Untreatable materials Iron, metal, cans, batteries, aluminum packaging bags, glass, bottles, stones, shells, concrete, bricks, PVC, items with high moisture content, powdered plastics/paper, sludge, inorganic materials Waste with high moisture content Diapers and other waste with high moisture content can be processed by mixing them with large amounts of wood chips, cardboard, etc. Big waste Big waste need to be cut so that it fits in the throughput window. |

イ Garbage contains a lot of waters can be treated by mixing with flammable waste

|

Garbage such as diapers, food waste and livestock droppings those contains a lot of waters can be treated by mixing with flammable waste. |

イ Lineups of Super Waste Processor

|

|

|

|

|

|

|

| Model | SWP-80 | SWP-100 | SWP-120 |

| Method | Magnetic decomposing | ||

| Processing capacity/ Day (Weight) |

0.5~1.0 ㎥ (0.15~0.3ton) ※Depends on the object |

1.0~3.0 ㎥ (0.3~0.9ton) ※Depends on the object |

2.0~5.0 ㎥ (0.6~1.5ton) ※Depends on the object |

| Power consumption | 8~11Kw/h | 10~21Kw/h | 10~21Kw/h |

| Electricity | 200V、Single phase、60ampare、50/60Hz | ||

| Tempereture | Outside body:50℃、Inide:600~800℃ | ||

|

Size WxDxH mm |

1,600 X 1,200 X 2,000 | 2,500 X 2,100 X 2,400 | 2,400X 2,100 X 2,600 |

|

Capacity of furnace |

0.36㎥ | 0.8㎥ | 1.2㎥ |

|

Weight |

800Kgs | 2,300Kgs | 2,600Kgs |

|

Items that can be decomposed |

Plastics, styrofoam, rubber, hardened paint, cardboard, paper, lumber, pallets, cloth, work gloves, clothing, tires, paper, organic materials with low moisture content | ||

|

Items that can not be decomposed |

Iron, metal, cans, batteries, aluminum packaging bags, glass, bottles, stones, shells, concrete, bricks, PVC, items with high moisture content, powdered plastics/paper, sludge, inorganic materials | ||

|

Other functions |

Furnace internal explosion pressure relief port, furnace internal waste height confirmation function, tar elimination function |

||

|

Option |

Automatic lifting and transport device, powerful vacuum cleaner, remote monitoring system |

||

イ There are big points!

|

|

|

|

|

|

| Applicable items | Unit | Standard | Result | Measuring methods |

| Dioxin | ng-TEQ-㎥ | 5 | 0.0058 | Rapid and simple analysis of dioxin |

| Soot | g/㎥N | 0.25 | Less than 0.01 | Meet the standard JIS Z-8808 |

|

Sulfur oxide |

㎥N/h | 0.08 | Less than0.01 | Meet the standard JIS K-0103 |

| Nitrogen oxide | c㎥/㎥N | 250 | Less than 10 | Meet the standard JIS K-0104 |

| Hydrogen chloride |

mg/㎥N | 700 | 0.9 | Meet the standard JIS K-0107 |

イ Places where you can solve garbage problems by introducing SWP

|

The pictures below from the left : beach full of trash, trash box on the city, bonfire on the field that causes forest fire, plastic garbage collection yard, waste tire collection site, world heritage places, national trust park, heavy snowfall areas places without garbage collection service, pacific islands, waste furniture after a typhoon/hurricane or earthquake. |

イ Movies of Super Waste Processor

イ Super Waste Processor at famous temple in Myanmar

イ Manufacturing SWP in your country

Japan's blue skies, blue seas, and clean rivers are maintained thanks to high-quality Japanese waste treatment equipment.1. In many countries around the world, garbage is buried in large open spaces. However, in Japan, garbage incineration began in 1972 with the enactment of the Waste Disposal Law.

2. In 1930, garbage incineration became mandatory in order to prevent the spread of infectious diseases and improve sanitary conditions.

As such, garbage incineration has a long history in Japan, and a wide variety of devices for various purposes have been developed.

3. Recently, small- and medium-sized devices that can be operated only on electricity without the use of gas or kerosene have been developed,

making it possible to easily dispose of waste from company factories and stores without relying on local governments.

4. Magnetic waste treatment devices were developed in Japan around 1990 as a unique technology, but the inventor did not want to patent the technology because he wanted many people to use the device.

However, companies in other countries copied the unpatented technology and created similar products.

5. Currently, there are manufacturers of magnetic waste processing devices in Asia, but since their designs only focus on magnetic decomposition, they lack the technology to eliminate carbon monoxide, carbon dioxide, and methane gas, leading to many explosion accidents among customers.

6. Japan's environmental laws are extremely strict, and incinerators and thermal decomposition processing devices must meet numerous stringent standards.

Without addressing all of these standards, it is impossible to sell such devices.

Japanese-made products are significantly superior to those made in other countries.

7. There is an environmental organization that extracts harmful gases from all magnetic thermal decomposition treatment devices in Japan and conducts thorough analysis tests.

The organization visits all manufacturers, connected pipes to the chimneys of the devices, collected the exhaust gases emitted, and conducted tests.

As a result, Super Waste Processor has consistently achieved perfect results with extremely low emissions of harmful gases in all categories, making it the number one recommended product by this organization.

If any company outside Japan wishes to manufacture SWP, we will gladly sell them the technology. The condition is that they must manufacture it in their own country and sell it only in their own country.

We will not provide support in the event of a malfunction. For this reason, we ask that they come to Japan at the time of signing the contract to learn the manufacturing methods and troubleshooting techniques from the manufacturer.

The US imposes high tariffs on imports from Japan. However, if a U.S. company manufactures the SWP within the United States, there are no tariffs.

Europe requires CE certification, which takes approximately two years to obtain, but if a European company manufactures the SWP, there should be no issues with the certification.

Other countries also face waste management challenges. If the SWP is manufactured in your country, we believe it will be possible to enjoy the same clear skies as in Japan.

If you are interested, please contact us.

Customers who viewed this item also viewed these products

|

|

|

|

|

|

Japanese products expected to increase sales in the future

|

|

|

|

|

|