|

What are active oxygen?

Active oxygen are said to be the strongest oxidizing capacity on earth. For example, in the process of converting oxygen taken into the human body through breathing, active oxygen play an essential role in maintaining life by instantaneouslysterilizing and decomposing bacteria and viruses through oxidative action so that they do not invade the body. However, it disappears in an instant.

If it can be kept for a long time or generated in excess, it destroys the brain and body cells, and is said to have such a high oxidizing effect that all life on earth will disappear.

It is also said that the aging of living organisms is caused by active oxygen generated in the body.Until now, there has been no way in the world to effectively utilize these active oxygen.

WEF Technology Development Co., Ltd. invented the world's first technology to generate a large amount of active oxygen in the atmosphere, and developed a compact active oxygen generator that can be used in various fields.In honor of his achievements, Mr. Aoyama was awarded the prestigious Order of Culture by His Majesty the Emperor in April 2022.

Organic matter is generally composed of carbon, hydrogen, and oxygen atoms that are very tightly bound together, making it difficult to decompose even with strong acids and alkalis, high temperatures, and high pressure.

The active oxygen generator "AOS," invented by WEF, can instantaneously decompose the strong atomic bonds of organic matter, and the device makes it possible to decompose organic matter by generating large amounts of active oxygen in the atmosphere.

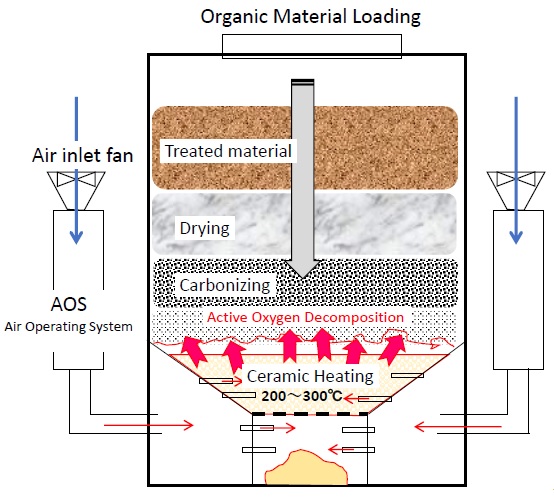

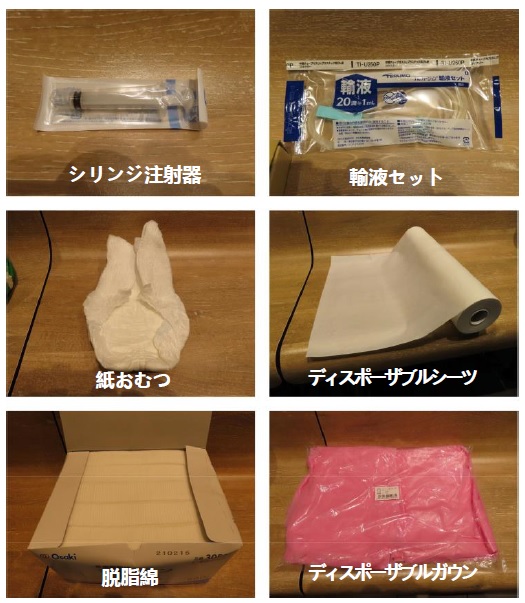

POLARIS is a solid organic waste processor capable of decomposing and treating petrochemical products, plastics, medical waste, disposable diapers, etc. by heating active oxygen at low temperatures.

|

The temperature at the time of decomposition is around 270°C and has not reached the ignition temperature of the substance. Also, the amount of oxygen input was so small that the material decomposed without combustion. All of the input is inorganic ash, and the volume reduction rate is 1/300 to 1/500. The volume reduction rate is 1/300 to 1/500.

The temperature at the time of decomposition is around 270°C and has not reached the ignition temperature of the substance. Also, the amount of oxygen input was so small that the material decomposed without combustion. All of the input is inorganic ash, and the volume reduction rate is 1/300 to 1/500. The volume reduction rate is 1/300 to 1/500.