Melt King MD Sterilizing dryer for medical waste and diapers

イ Dry, sterilize and reduce volume of diapers and infectious medical waste

|

|

|

|

Possible to reduce volume max 98%

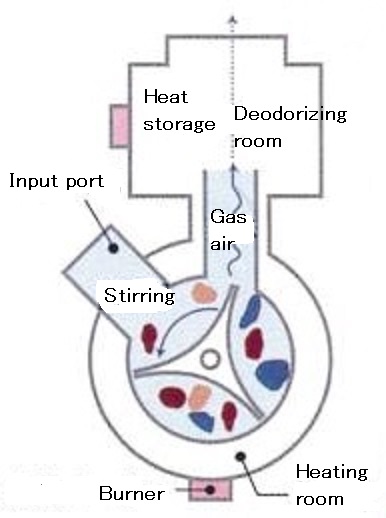

Garbage, food waste are cut off oxygen in the reduction room and indirectly heated and dried to achieve significant weight loss. The weight loss rate depends on the type of treated material and the water content , and a maximum weight loss of 98 % is possible. For example, food waste will be reduced to 98%.

|

|

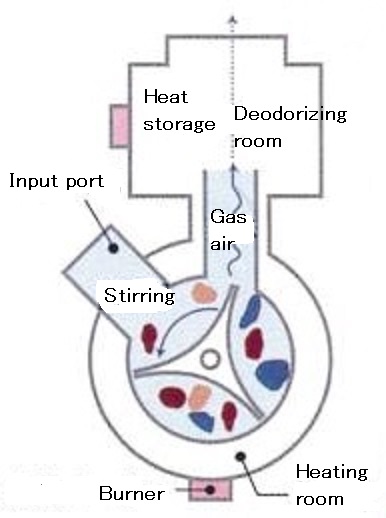

No dioxin, dust scattering and smell

Because it is indirect heating, there is no scattering of dust, and it is an eco-friendly system that does not generate dioxin because it does not incinerate. Patented deodorizing technology significantly reduces odor during heating and reducing driving noise.

|

|

Significant processing cost reduction

Originally, it costs a lot to manage and dispose of it as industrial waste, but by introducing it, it is possible to greatly reduce the treatment cost.

|

Prevention of confidential documents leakage

It can also be used to process important documents.By processing in the facility, it is possible to prevent leakage of confidential information and personal information.

|

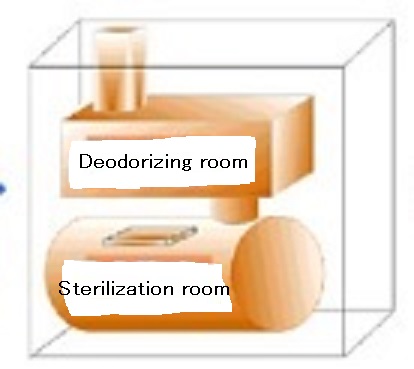

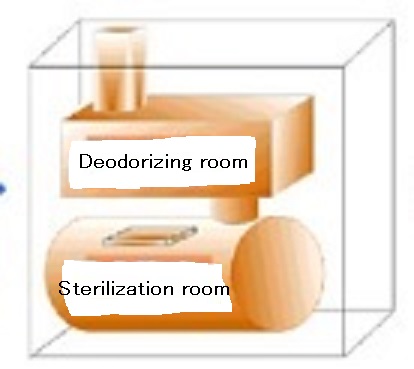

Safety that can be used in residential areas

Both the weight loss room and the deodorization room have a double structure, ensuring high safety. The processing temperature in the weight reduction chamber is as low as about 180℃ambient temperature, and there is no oxidation reaction, so the equipment lasts longer. With a vibration sensor, it responds to emergencies.

|

Effective use of recycled waste

Since there is no combustion(oxidation reaction) of the processed material in the weight loss room, the processed material is not ash but a combustible solid. Most of the calorie solid fuel can be recycled. Depending on the content of the processed material, it can be recycled into feed and fertilizer.

|

| Easy Operation

Easy operation has been achieved in pursuit of operability and safety. Safety operation makes it easy to load and discharge processed materials.

|

| Possible of fast and hygienic treatment

The introduction inside the facility enables quick processing of the waste and improves the sanitary environment of the facility.

|

| Melt King PDF brochure |

| Contact us |

|

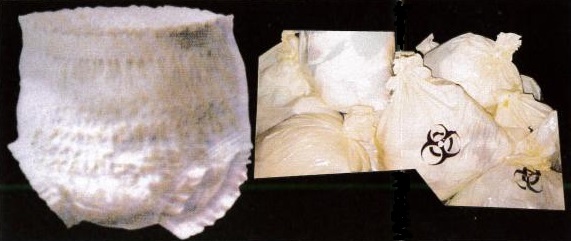

イ Objects Melt King MD can process

Diapers, medical waste, infectious waste

イ Customers cases of Melt King MD

Hospital City hospital Rehabilitation center Inspection service company

Hospital City hospital Rehabilitation center Inspection service company

MD-500 MD-1000 MD-1000 MD-1000

Diapers Diapers Diapers Blood

イ Model lineups of Melt King MD

| Model |

MD-500 |

MD-1000 |

Can

process |

Diapers, gauze with blood, absorbent cotton, bandages, infectious waste etc.

|

Can not

process |

Vinyl chloride products, petroleum, oil, metal, iron, glass, stone, porcelain, bound paper or books, large amount of cloths / plastic, etc

|

|

Size WxDxH

|

1,910 × 1,350 × 2,425 mm

|

2,340 x 1,510 x 2,535 mm

|

|

Exhaust tower

|

400mm |

|

Weight

|

1,900kgs |

3,000Kgs |

|

Process

capacity

|

500 litters/ badge |

1,000 litters / badge |

|

Inlet size

|

650 X 400 mm |

|

Electric power

|

3 phase 200 voltage

|

|

Power

consumption

|

1.3kw/h |

2.3kw/h |

| Fuel1 |

Kerosene JIS No.1

|

Fuel

consumption |

6~8 litters/ h |

8~13 litters / h |

Fuel 2

In case of gas |

City gas 13A 2kpa

Can be changed to LPG

|

Gas

consumption |

4~6㎥ / h |

5~9.6㎥ / h |

Processing

time |

6~10 h / badge |

8~13 h / badge |

| Accessory |

Kerosene use : Kerosene tank ( 198 liters), cleaning stick, saucer, grease

Gas use : cleaning stick, saucer, grease

|

Customers who viewed this item also viewed these products

Japanese products expected to increase sales in the future